您的當(dāng)前位置:首頁 > 業(yè)務(wù)中心> 其他> 背板背板

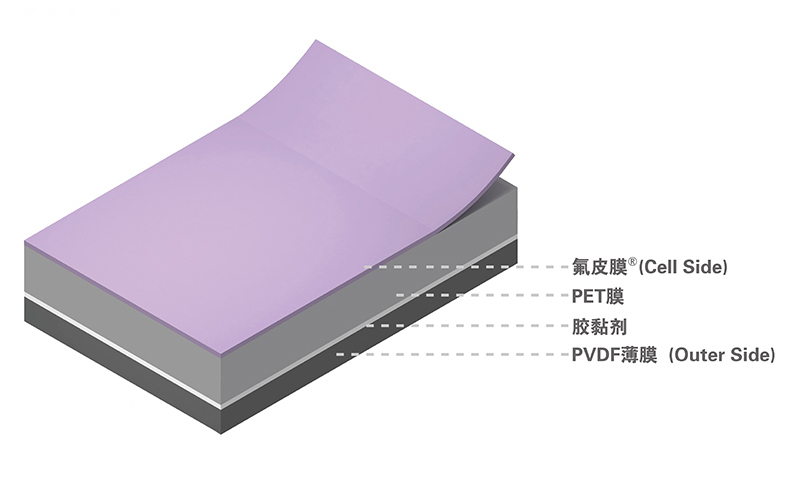

背板-Cybrid KPF

產(chǎn)品詳細(xì)介紹

產(chǎn)品特點

■ High resistance to heat and humidity

■ Excellent Sand Falling Test

■ Excellent partial discharge

■ High Inner Layer Reflectivity

■ Excellent UV Blocking

■ Excellent Thermal Conductive

■ High Water Barrier

■ Easy to Rework

產(chǎn)品規(guī)格

| Specification | Unit | Cynagard 205A | Cynagard 215A | Cynagard 225A | Standard | |

| Product thickness | um | 295.0±10% | 300.5±10% | 300.5±10% | ASTM E252 | |

| Tensile strength(MD/TD) | MPa | MD≥100 TD≥100 | MD≥100 TD≥100 | MD≥100 TD≥100 | ASTM D-882 | |

| Elongation of break(MD/TD) | % | MD≥100 TD≥80 | MD≥100 TD≥80 | MD≥100 TD≥80 | ASTM D-882 | |

| Heat shrinkage (MD/TD) 150℃*30min | % | ≤1.5 | ≤1.5 | ≤1.5 | ASTM D1204 | |

| PVDF/PET peel strength | N/cm | ≥4 | ≥4 | ≥4 | ISO 8510 | |

| Coating/PET adhesion | Level | 0 | 0 | 0 | ISO 2409 (Cross-Cut Method) | |

| BS/EVA peel strength | N/cm | ≥40 | ≥40 | ≥40 | ASTM D903 | |

| Inner layer reflectivity | % | ≥80 | ≥80 | ≥80 | ASTM E1164 | |

| Falling Sand Test | L | ≥100 | ≥100 | ≥100 | ASTM D968 | |

| Water Vapor transsmision 38℃ 90%RH (IR) | g/m2 .day | ≤2.0 | ≤2.0 | ≤2.0 | ISO15106-3 | |

| Adhesion to potting/sealant | Visual | Cohesive Failure of potting/sealant | Cohesive Failure of potting/sealant | Cohesive Failure of potting/sealant | ASTM D903 | |

| Breakdown Voltage | KV | ≥16 | ≥16 | ≥16 | ASTM D-149 | |

| Partial discharge | VDC | ≥1000 | ≥1000 | ≥1000 | IEC 60664-1 (TüV Rheinland Certification) | |

| TI | ℃ | 120 | 120 | 120 | IEC60216 (TüV Rheinland Certification) | |

| FSI | — | <100 | <100 | <100 | ASTM E 162 (TüV Rheinland Certification) | |

| Boiled① (24H) | PVDF/PET peel strength | N/cm | ≥3.5 | ≥3.5 | ≥3.5 | ISO 8510 |

| Coating/PET adhesion | Level | 0 | 0 | 0 | ISO 2409 (Cross-Cut Method) | |

| DH② (1000H) | Yellow index | Δb | <4 | <4 | <4 | ASTM E313 |

| PVDF/PET peel strength | N/cm | ≥3.5 | ≥3.5 | ≥3.5 | ISO 8510 | |

| Coating/PET adhesion | Level | 0 | 0 | 0 | ISO 2409 (Cross-Cut Method) | |

| UV③ (90KWH) | Yellow index | Δb | <4 | <4 | <4 | ASTM E313 |

| PVDF/PET peel strength | N/cm | ≥3.5 | ≥3.5 | ≥3.5 | ISO 8510 | |

| Coating/PET adhesion | Level | 0 | 0 | 0 | ISO 2409 (Cross-Cut Method) | |

| TC④ (200) | Yellow index | Δb | <4 | <4 | <4 | ASTM E313 |

| PVDF/PET peel strength | N/cm | ≥3.5 | ≥3.5 | ≥3.5 | ISO 8510 | |

| Coating/PET adhesion | Level | 0 | 0 | 0 | ISO 2409 (Cross-Cut Method) | |

| HF⑤ (10) | Yellow index | Δb | <4 | <4 | <4 | ASTM E313 |

| PVDF/PET peel strength | N/cm | ≥3.5 | ≥3.5 | ≥3.5 | ISO 8510 | |

| Coating/PET adhesion | Level | 0 | 0 | 0 | ISO 2409 (Cross-Cut Method) | |

Remark:Samples treated in ①boiled water ② 85%/85%RH.③60℃④-40℃~85℃⑤-40℃~85℃,85%RH